Share

Pin

Tweet

Send

Share

Send

This is an instruction (guide) on how to make a cheap convenient and portable device for spot welding of metal out of a damaged microwave oven.

Please note that this is dangerous, as indicated by the inscription on the transformer: "DANGEROUS HIGH VOLTAGE", take all possible precautions by following these instructions:

Materials

The meager cost of this spot welding can be generally reduced to zero, if you find the following accessories without resorting to buying:

1. Very old microwave - can be found in a landfill.

2. A wooden board.

3. T-shaped brackets.

4. Screws.

5. A cable with a diameter of 1 cm with a solid core is also suitable for multi-core, but make sure that each thread has a diameter of at least 1 mm.

6. Other woodworking tools and electrical connectors.

7. 3-pin connectors (optional).

8. Metal jumper for fastening at least 15cm long (optional).

9. Connector from PC power supply (optional).

10. Terminal block (inner diameter 1 cm).

We take out the transformer from the microwave

This step describes how to remove the transformer from the microwave.

1. Disassemble the microwave without touching any elements on the circuit boards.

2. Find a high voltage capacitor, it should be attached to the capacitor and look like a magazine from a gun with 2 wires coming from one end.

3. Short-circuit the capacitor with a screwdriver. ATTENTION: IT IS NOT NECESSARY TO WATCH THIS; SPARK IS VERY BRIGHT, MAY DAMAGE VISION.

4. Remove the transformer.

The structure of the resistance welding machine

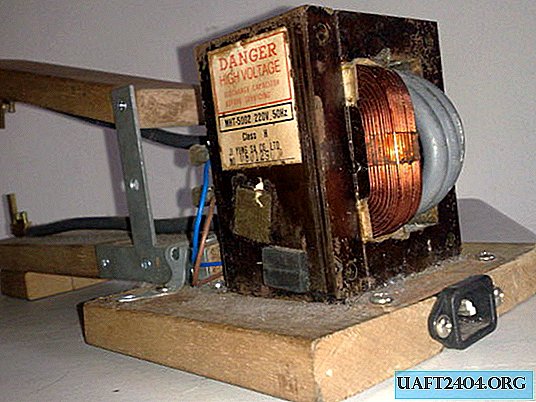

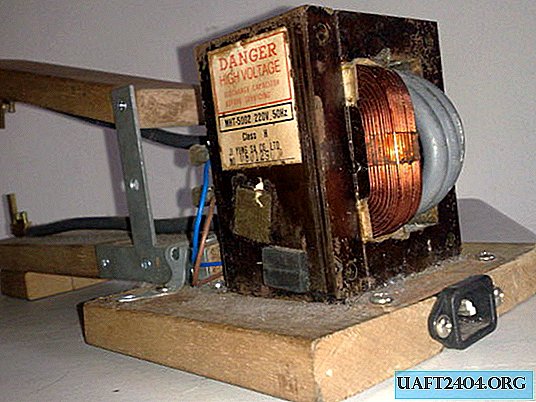

This whole structure is made of one wooden board and the only modification that needs to be made is to cut the board to a certain length, so that all the parts have the same height.

As can be seen from the figure, the two middle parts form the base on which the transformer is mounted, between them is the power supply power connector.

On the front panel are two long parts connected by T-shaped brackets (do not tighten the upper screws, this should be a flexible connection).

Two electrodes are missing at the front end, attach them at the bottom of the long part, attach the long part to the short one for added stability and support.

Electrodes

Anyone who has experience in welding knows that at extreme temperatures the electrodes melt very quickly, I puzzled over the solution to this problem and realized that the grounding pin of 3-pin plugs can be used as electrodes, they are widely available and cost a penny, and then he developed a method of attaching them to the welding equipment and a replacement strategy (so that they can be replaced as easily as a drill with a drill). Below is an example of creating your own electrodes for this unit:

1. Separate the 2 3-pin plugs and remove the ground pins (the longest pin).

2. Separate the two parts of the terminal block and assemble the metal parts.

3. Screw the earth pin into a piece of copper scrap and place it in the metal pin of the terminal block, tighten the metal pin all the way.

4. Screw the metal pin of the terminal block into a wooden board with the free end pointing towards the transformer, they will be attached to the ends of the cable with a diameter of 1 cm.

Electrical modifications of the apparatus

The secret to successful spot welding is to control the passage of a large amount of current through the welding point and generate the required temperature, which is quite difficult to achieve because of the resistance of the materials.

However, the secondary winding of the microwave transformer has the opposite purpose, it contributes to a significant increase in the mains voltage by reducing the current, so it must be modified if you want the welding machine to work. How to do this is described below:

1. Remove the secondary winding of the microwave transformer (this is a winding that is not connected to the network, has a wire of smaller diameter and more convolutions), for this I used an angle grinder with a cutting blade to cut through the entire piece. Although the primary windings cannot be damaged by spot welding, I would advise caution.

2. Using a cable with a diameter of 1 cm, make as many loops as possible through the space where the secondary windings used to be (in my case it was 3), then lengthen the rest of the cable to the front part on which the electrodes are located, and attach them, after screwing the finished transformer on the base plate of the structural frame.

3. Some of you may notice the PSU power connector under the transformer, I took it from the damaged computer power supply.

Other details

Pay attention to how I strengthened the structure by securing the middle board with a metal jumper. The microwave transformer is incredibly heavy.

Brown and blue wires that are attached to the primary coil are connected to the power connector mentioned above.

You can make some more improvements: completely close the transformer (create an external protective casing) and add a cooling system inside to ensure safety and extend the operating time, since it heats up during use, but I prefer the harsh version, as it is now.

Original article in English

Share

Pin

Tweet

Send

Share

Send