Share

Pin

Tweet

Send

Share

Send

Will need

In principle, nothing expensive or scarce is required for this work. From the materials should be stocked:

- wooden plank;

- double-sided tape;

- 3 V power supply (batteries, accumulator);

- plastic transparent box with a lid;

- on-off switch.

In the upcoming work, we will have to use:

- pendulum or any other saw;

- bench drilling machine;

- hand grinding stone;

- wallpaper knife;

- electric soldering iron.

The main thing here are two azure modules that were purchased at Ali Express (//ali.pub/3if3b7). These laser pointers do not give out a point, but a flat line that you can simply customize.

Production and installation of a laser pointer on the machine

Even a high school student can handle the upcoming work. The most difficult operation of the upcoming, probably, soldering wires.

Using a pendulum or any other available saw, we cut two identical parallelepiped bars from a wooden workpiece.

We drill in wooden blocks closer to one edge of the hole of the desired diameter on the drilling machine.

We process the bars with the help of a hand grinding stone to give them an attractive appearance and ease of use.

We cut off with a knife a knife two identical strips of double-sided tape, tightly wrap them with two laser LEDs and insert them into the holes in the wooden blocks.

Using double-sided tape, we attach wooden blocks with laser LEDs on the fixed spindle limiter (it was made on a 3D printer, but it can also be cut from wood itself) at an angle of 90 degrees relative to each other.

Health Check

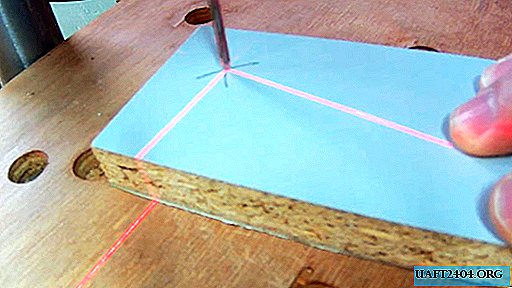

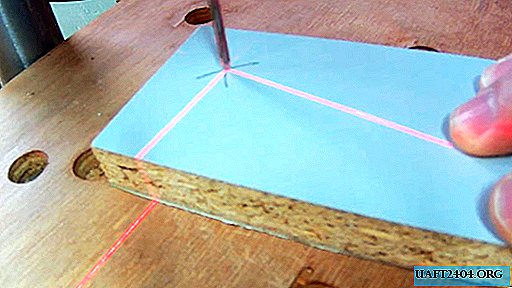

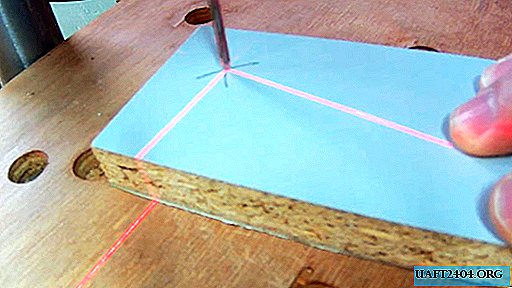

The power source is a 3 V flat battery. We mark a point on the workpiece with two intersecting straight lines.

We draw the point marked on the workpiece under the lines intersecting at right angles created by laser LEDs.

We achieve the coincidence of the coordinates of the point marked on the workpiece with the intersecting rays reproduced by laser LEDs, and we perform the drilling process.

We are convinced that the drilling was carried out exactly in accordance with the markings we made earlier.

Once again, we repeat the procedure for positioning the workpiece in relation to the drill using laser LEDs, drill and again ascertain the accuracy of the operation. It should be borne in mind that we use a drill is not the coolest, and the cartridge has a backlash.

Mount the switch in the housing

In order not to waste the energy of the batteries supplying the laser LEDs, we set the on / off switch on / off between them. For this we use a transparent plastic box with a lockable lid.

At the bottom of the box with a drill with a thin drill, we make a hole where a two-position switch will subsequently be installed.

We drill it to the required diameter using a step drill fixed in the drill chuck.

We insert the switch from the outside into the hole in the plastic box so that the "0-1" key is outside. On the side of the box, enter the wires through the hole provided for them.

Using a soldering iron and solder, we connect the wires in the following order: "+" batteries with "+" LEDs, "-" batteries with a switch, switch with "-" LEDs. Close the lid of the plastic box.

Using double adhesive tape, we fasten the plastic box with the on / off switch to such a place on the body of the drilling machine so that it is completely safe and, at the same time, convenient for turning the laser LEDs on and off.

Share

Pin

Tweet

Send

Share

Send