Share

Pin

Tweet

Send

Share

Send

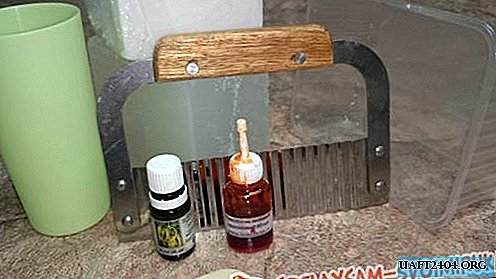

Tools & Parts

Two plastic pipes for plumbing 50 cm long with a diameter of 40 mm and 32 mm, two plugs for them, a coupler with a diameter of 40 mm, an angle of 45 degrees for Ø 32 mm and an angle of 90 degrees for 32 mm in diameter are also needed. Additional sealing is done with a special rubber sleeve. Valves are made of a sheet of rubber or other waterproof material with a thickness of 1-2 mm. Preparation of plastic elements is done with metal scissors. Additionally, you need to prepare a piece of twine, silicone grease and a lighter. The cap is glued with a thermal gun or any waterproof glue.

Manufacturing technology

Connect the two corners; if the rubber seal is tight, use special grease.

A pipe with a diameter of 40 mm is the barrel, and a pipe with a diameter of 32 mm is the piston of the pump. Thickening on a thin one does not allow you to enter the barrel, it must be cut with scissors for metal. If the pipes are from unscrupulous manufacturers, then they are made of low-quality plastic and crack. Work carefully, before cutting, remove the sealing rubber from the socket.

Insert the pipes into each other and check the stroke density, the efficiency of the pump depends on this.

From the plugs, make two drips, one on the piston, the second on the pump barrel. For the manufacture you need to have rubber or tarpaulin. Place the material on a flat surface, press the cap firmly against it. A valve outline should appear. Gently cut the workpiece with scissors.

It is not necessary to make an ideal round, the main thing is that in diameter it freely enters the pipe.

Now it is necessary to fix the valve and prepare a hole for water inlet / outlet. They can be made with ordinary scissors or the edge of a knife, but it is much better to work with a notch.

Insert the valve into the plug and, closer to the edge, punch a small hole in both parts to secure it. With a larger diameter slot, punch the second hole only in the water plug, position it opposite the first. If there is no big cut, then it can be increased with a knife or scissors.

Fasten the valve to the plug. From a synthetic twine, cut a small piece 1-2 cm long, work with a lighter. Point the ends of the twine with your fingers, be careful not to burn yourself. On one side make a mushroom (rivet). To do this, heat the end and press it against the metal part of the lighter.

Put the valve on the mushroom, insert it into the plug, and put the end of the rope into the small hole. On the reverse side, cut off the excess rope, melt it and fasten it to the surface of the stub.

Check the operation, blow into the plug from both sides, the valve must be torn off to allow air to pass through and then close tightly.

Using the same algorithm, a second valve must be made. Insert a large valve into the bell of a pipe with a diameter of 40 mm, fixing it with hot glue, this part is ready.

The sealant has been removed from the small tube - to seal the plug, first coat it with silicone hot melt adhesive. After curing with scissors, remove the protruding parts of the joint.

Reassemble the pump housing and check the piston stroke. It should be tight, but without jamming.

Seal the piston rod outlet from the barrel. This is done using a coupling and a special rubber seal. The sealant allows you to make tight connections of pipes of various diameters, we have just such a situation.

Remove the standard rubber gland from the coupling. Cut one petal from the special ring, it too much reduces the conditional passage of the hole, the pump will wedge. Remove excess length with scissors.

Insert the prepared seal into the coupling - the adapter for connecting pipes of different diameters is ready.

Try on all the details. It is necessary to ensure that the piston does not reach the start of the socket on the barrel pipe. Put parts on one line and make accurate measurements in assembled condition. In our case, we need to reduce the barrel length by 2.5-3 cm, cut off an unnecessary piece.

Put the adapter on the end of the small diameter pipe, assemble the pump and put the coupling on the pipe of larger diameter.

On dry rubber seals the piston stroke is very tight, lubricate the surface with silicone grease. Remove price tags immediately, make the piston run smoothly.

The device is ready, check its performance. Transfer water from one bucket to another, if everything is normal, then you can take the pump with you in a boat trip.

Conclusion

Such a pump can be used in the country to pump various liquids. Practice shows that it is not worth increasing the diameter of the pipes to increase productivity - it is too hard to work with the device.

Share

Pin

Tweet

Send

Share

Send