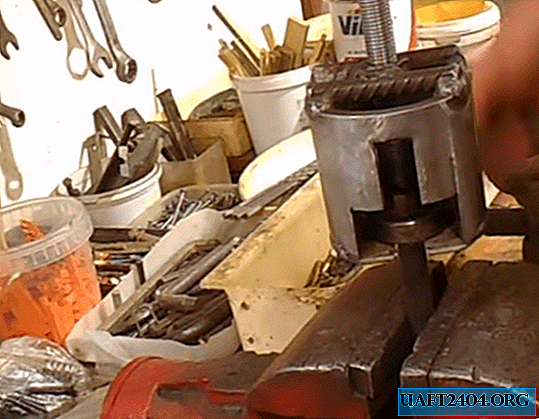

Threaded rivets are used in cases where it is necessary to connect products from sheet metal with bolts. For example, a piece of metal strip and a profile pipe.

To install them you need a rivet. But in this review, the master makes a homemade device.

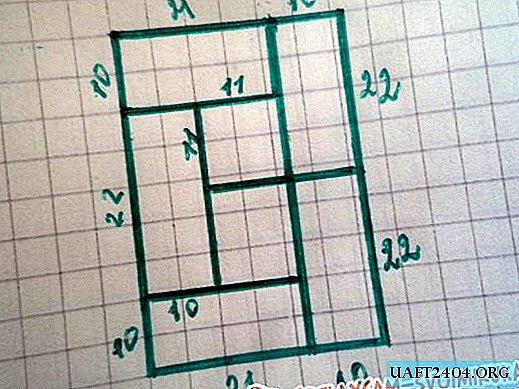

To make this adapt, you will need a piece of a profile pipe, a workpiece from a metal strip, an elongated nut, bolts and nuts. An electric drill is used as a drive.

We recommend you to read: how to make a simple home-made rivet for do-it-yourself rivets.

The main stages of work

The first step is to weld a bolt to an elongated nut. Then cut off two pieces of a metal strip and weld them on the sides of the nut.

Further, in the section of the profile pipe, the author makes cuts under the plates welded to an elongated nut.

We screw an ordinary nut onto the second bolt, then we put on a plate with a hole and a washer. It must be welded to the thread.

We screw this part into an elongated nut, which we insert inside the profile pipe. We weld a plug to the end of the profile, in which a hole for the bolt is provided.

At the last stage, it remains only to shorten the first bolt and cut off the hat at the second bolt. The author welds a second elongated nut to the profile pipe, into which the handle from the angle grinder is screwed.

For details on how to make a device for installing threaded rivets, see the video.