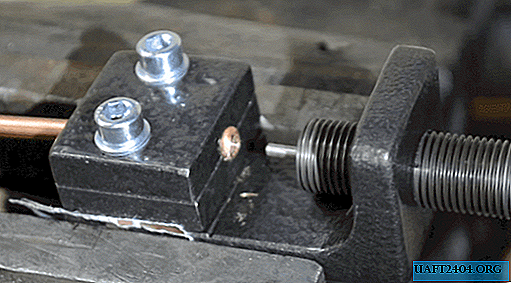

Clamp - an indispensable thing in any suburban area. And you can make it yourself from improvised materials, which are almost always found in the garage and home workshop.

To make a home-made classic clamp, you need two elongated (transitional) nuts, a hook from the turnbuckle and an M8 nut

Also required are furniture bolts with a flat head with a size: 10 * 40 mm, 8 * 140 mm, 10 * 100 mm.

First of all, to make the clamp, you will need a hook from the lanyard and a bolt 10 * 40 mm. Using the adapter nut, connect the hook and bolt together.

In this case, the hook will be a handle, the nut will be a special tensioner holder, and a bolt 10 * 40 mm serves as a tip for the clamp.

The main stages of work

For reliable connection of the handle with the tip, the author drills two holes for rivets in an elongated nut.

On the side you will need to drill another 10.5 mm hole for the tensioner. Drilling holes can be done either on a drilling machine or with an electric drill.

However, in order to make the drill easier to hook, it is necessary to grind the face of the nut a little with a grinder.

From the bolt, which serves as the tip, you need to cut off the cap with a grinder, and sharpen the end and make a "groove" for the wire. The author closed the thread on the hook pin with a piece of rubber hose.

At the last stage of work, it will be necessary to make the clamp tensioner itself.

To do this, insert a bolt into the hole in the adapter nut, drill holes for the wire in it, wind an extended nut on the thread, and cut off the excess with a grinder.

Two holes will also need to be drilled in the elongated nut: one to fix the tensioner, and the second to install the knob.

After this, it remains only to assemble the device. The detailed manufacturing process of the classic clamp can be found in the video on the website.