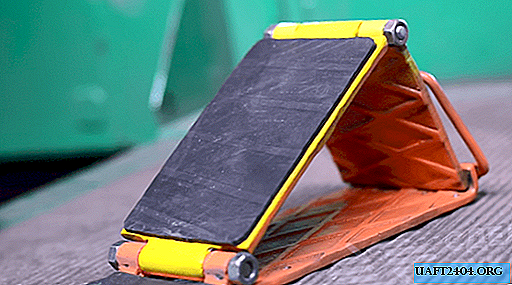

The master decided to replace the "native" tubular frame, and make the so-called beam, in which the canvas is stretched. The design itself is quite simple, if desired, any master can repeat it.

A beam consists of several basic elements connected together: two racks with a spacer between them, as well as a tension bow (hemp rope), which is twisted with the help of a “flag” and pulls the saw blade.

As the main material for the manufacture of uprights and struts, a copper tube is used. However, you can take aluminum or even steel. The first step is to cut off three workpieces of the required length.

The process of manufacturing a metal frame (beam)

In the racks in the middle, drill holes for the jumper. At the bottom of the racks, the master makes slots for installing the saw blade, which is fixed with two bolts and wing nuts.

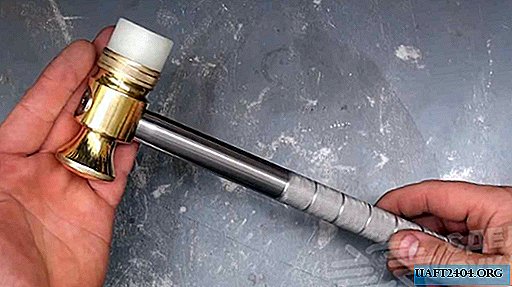

At the top of the racks you need to drill one through hole for the bowstring. The master makes a flag from a wooden bar. In principle, you can’t imagine anything more practical in this case.

The advantage of this design is the ability to quickly assemble and disassemble. Therefore, such a beam saw without problems can be taken with you to the country, for example. In general, practical and convenient at the same time.

In detail about how to make a metal frame for a bow saw, you can see in the video on our website. Write in the comments, did you like this homemade product?