A simple metal chip collector made of neodymium magnets and a regular hollow tube is useful both in the garage or in the country house, and in the home workshop (especially if you often perform work on a metal lathe).

Magnetic chip picker allows you to quickly collect small parts and sharp chips formed after processing metal blanks, without direct contact with hands. For this, it is best to use neodymium magnets, since they are more powerful than ordinary ones.

The principle of operation of a home-made device is very simple - pass the tube over the place where a lot of metal chips have accumulated, then bring the chip collector to the waste storage container or bin, and then pull the handle with the magnet back and the chip under its own weight falls down.

The main stages of work

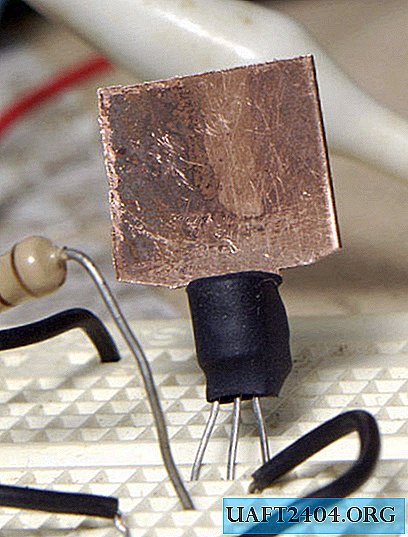

To make a homemade metal chip collector, you will need a small piece of a hollow tube made of copper or aluminum. A plug must be installed at one end. Then on the segment of the stud we “push” round neodymium magnets with a hole in the center (6-8 pieces will be enough).

Next, you will need a piece of steel bar, in the end of which we drill a hole and cut the thread to the diameter of the stud. Then we screw the pin itself with neodymium magnets. In the tube it will be necessary to additionally install a thick-walled washer.

In the next step, insert the rod with the pin into the tube, and plug one end with a plug. At the end of the steel bar, we cut the external thread, after which we put a rubber handle on it and wind the knob of plastic or wood.

For more information on how to make a simple collector of metal shavings from magnets with your own hands, see the video on the website.