So that when laying the floorboard or when replacing the old floor in the house and apartment (or in the country), cracks and gaps do not form between the individual floorboards, you need to tighten them well. And this will help a simple device to tighten the floorboards.

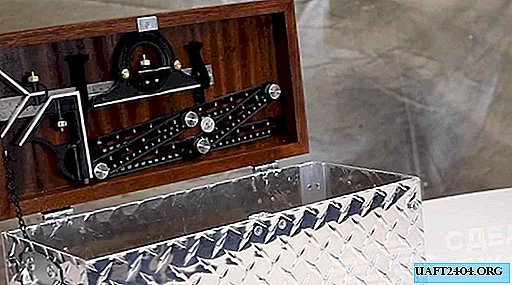

The tool is sold in the store. But why overpay when you can do it yourself without problems? For its manufacture, segments of the profile pipe of different sizes and studs with nuts and washers will be required.

Step-by-step tool manufacturing process

We take two pieces of a square profile (short and long) and drill holes in them of the right diameter for the M8 hairpin. We cut a short section of the profile pipe on one side at an angle of 45 degrees, insert it into the holes of the studs and fix them with nuts and washers.

Then we join two profile pipes with each other by means of a stud with a nut. The result should be a movable structure. Next, to a long section of the profile, it is necessary to screw a piece of the profile pipe with a length of 15 cm, which will serve as an abutment when pulling the floorboard.

Using this tool is very simple. We install the device on the lag (at the required distance), and then turn the handle-lever clockwise until the stop presses the floorboard. You need to push about the middle of the floorboard. A detailed process of manufacturing devices for tightening floor boards, see the video on the site.