Plywood, chipboard, OSB, drywall and other sheet materials, which are large in size, are very inconvenient to carry alone. But what if there is no partner, but you need to work? In this case, a mini conveyor will help out, which can be done with your own hands from available materials.

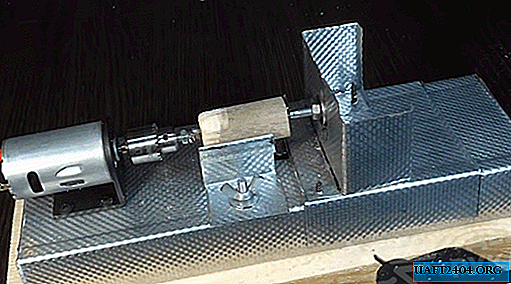

To work, you will need steel corners and round rods of different sizes, a pair of bolts with nuts and two plastic wheels. Of the main tool, only a welding machine and angle grinder will be needed.

Manufacturing process

To a piece of steel corner (at a distance of about 3-4 cm from the edge), it is necessary to weld one bolt with a nut. On the inside of the corner along the entire length, we weld another smaller corner. In the center of the free shelf (from the outside), you will also need to weld the end of the round rod.

For greater rigidity and reliability to the steel bar, it is necessary to weld the jibs on both sides - it is best to make them from the corner, but it is also possible from reinforcement, for example. At the other end of the round, by welding, we attach a handle made of a steel bar of a smaller diameter (you can give it a suitable shape on a bending machine).

The last stage of work

All places of welds, as well as the surface of the metal, are well cleaned with a grinder with a grinding wheel. Then, the resulting design, if desired, can be painted with spray paint for a more presentable appearance. The mini conveyor is now fully assembled and ready to use. All stages of the work can be seen in the video on our website.