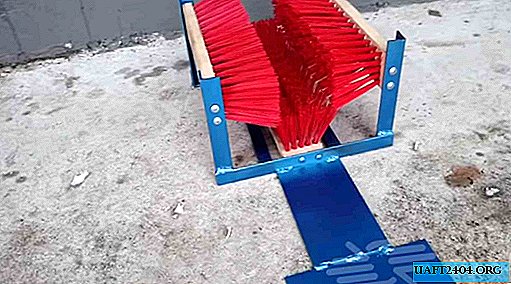

With this homemade product, you can quickly and easily cut round holes of different diameters from tiles. Of the basic materials for its manufacture, you will need an angle grinder, a special nozzle for a grinder with a 6.5 mm core Dimand Core Bits, as well as a piece of an equal-angle metal corner, a stud and several nuts for it.

Work stages

First of all, on one side of the corner you need to make a narrow slot for almost the entire length of the segment, and on the other side, drill a hole for the stud.

On the stud itself, you first need to sharpen one end with a grinder, and then insert it into the hole in the corner and fix it with two nuts, which then need to be gripped by electric welding.

Further, all places of the welds are well protected with a brush for metal, and then to the end of the stud, which is not pointed, we weld a short piece of steel bar perpendicularly.

After that, it remains to screw an additional (clamping) nut onto the stud and you can already start painting the parts.

Assembly process

Before starting work, install the Dimand Core Bits nozzle on the grinder. The handle of the grinder must be inserted into the slot of the corner and screwed to the body of the power tool. After that, we simply screw the pin into the hole in the corner, securely fix it with the clamping nut and you can get to work.

The device is very compact and practical to use. The detailed manufacturing process and the application of this homemade product in practice, see the video on our website.