A homemade mini circular saw is ideal for sawing small blanks from sheet materials: plywood, MDF, fiberboard and chipboard. This version of the machine has compact dimensions, so it does not take up much space on the desktop.

To make mini circulars you will need:

- 775 electric motor with bracket;

- two case bearings;

- small circular saw;

- adapter with quick-lock nut;

- aluminum pulley with belt.

You will also need screws and screws to secure parts. The seat for the circular saw and the working table are made of MDF scraps of different sizes.

Of the auxiliary components for the manufacture of mini-circulars, wires and a toggle switch on / off the engine will be required. In general, the design of this machine is very simple, so everyone can do it.

The main stages of work

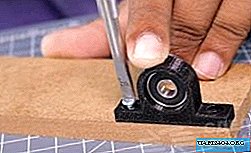

From the MDF plate we cut a small piece of a rectangular shape (dimensions - 160x60 mm) and fasten two case bearings to it. A bracket with a DC motor is mounted on the opposite side of the base.

A plastic tube is inserted into the bearings, and a metal rod with a diameter of 5 mm is inserted into it. An aluminum pulley and adapter with nut for attaching a circular saw are put on the shaft.

We connect the engine pulley to the driven shaft using a belt. We make the working surface from a piece of MDF with dimensions of 460x310 mm. We attach to it a platform with a motor and bearings, install a circular saw and a guide.

At the last stage of work, it remains only to connect the switch to the engine, and the motor itself to the power supply. You can see the step-by-step process of manufacturing mini-circulars in the video on the website.