Share

Pin

Tweet

Send

Share

Send

Hello dear ladies and gentlemen!

On this page, I will briefly tell you about how to remake the power supply of a personal computer with my own hands into a charger for car (and not only) batteries.

The charger for car batteries should have the following property: the maximum voltage supplied to the battery is not more than 14.4V, the maximum charging current is determined by the capabilities of the device itself. It is this charging method that is implemented on board the car (from the generator) in the normal mode of operation of the car’s electrical system.

However, unlike the materials from this article, I have chosen the concept of maximum simplicity of improvements without the use of home-made printed circuit boards, transistors and other "bells and whistles".

A friend gave me the power supply for the alteration, he himself found it somewhere at his work. From the inscription on the label it was possible to make out that the total power of this power supply is 230W, but a current of no more than 8A can be consumed through the 12V channel. Opening this power supply, I found that it does not have a chip with the numbers "494" (as described in the article proposed above), and its basis is the UC3843 chip. However, this microcircuit is not included in a typical way and is used only as a pulse generator and a power transistor driver with overcurrent protection function, and the functions of the voltage regulator on the output channels of the power supply are assigned to the TL431 microcircuit installed on an additional board:

A trimming resistor is installed on the same additional board, allowing you to adjust the output voltage in a narrow range.

So, to remake this power supply into a charger, you first need to remove all unnecessary. The excess is:

1. 220 / 110V switch with its wires. These wires just need to be removed from the board. At the same time, our unit will always work from a voltage of 220V, which eliminates the danger of burning it if the switch is accidentally switched to 110V;

2. All output wires, with the exception of one bundle of black wires (in a bundle of 4 wires) is 0V or "common", and one bundle of yellow wires (in a bundle of 2 wires) is "+".

Now we need to make sure that our unit always works if it is plugged into the network (by default, it only works if the necessary wires are shorted in the output wire bundle), and also eliminate the overvoltage protection action, which disconnects the unit if the output voltage is ABOVE some specified the limit. This is necessary because we need to get a 14.4V output (instead of 12), which is perceived by the built-in block protections as an overvoltage and it turns off.

As it turned out, the “on-off” signal and the signal of the overvoltage protection pass through the same optocoupler, of which there are only three - they connect the output (low voltage) and input (high voltage) parts of the power supply. So, so that the unit always works and is insensitive to output overvoltages, it is necessary to close the contacts of the required optocoupler with a jumper from the solder (that is, the state of this optocoupler will be "always on"):

Now the power supply will always work when it is connected to the network and no matter what voltage we make at its output.

Next, it should be installed at the output of the unit, where it used to be 12V, the output voltage is equal to 14.4V (at idle). Since only using the rotation of the tuning resistor installed on the additional board of the power supply unit, it is not possible to install 14.4V at the output (it allows you to do something somewhere around 13V), it is necessary to replace the resistor connected in series with the tuning resistor with a slightly smaller one nominal, namely 2.7kOhm:

Now, the output voltage setting range has shifted upwards and it has become possible to set the output to 14.4V.

Then, you need to remove the transistor located next to the TL431 chip. The purpose of this transistor is unknown, but it is turned on so that it can interfere with the operation of the TL431 chip, that is, prevent the output voltage from stabilizing at a given level. This transistor was located at this place:

Further, in order for the output voltage to be more stable at idle, it is necessary to add a small load to the output of the unit via the + 12V channel (which we will have + 14.4V), and the + 5V channel (which we do not use). A 200 Ohm 2W resistor is used as a load on the + 12V channel (+14.4), and a 68 Ohm 0.5W resistor is used on the + 5V channel (not visible in the photo, because it is located at an additional charge):

Only after installing these resistors, it is necessary to adjust the output voltage at idle (without load) at 14.4V.

Now it is necessary to limit the output current to a level acceptable for a given power supply unit (i.e., about 8A). This is achieved by increasing the value of the resistor in the primary circuit of the power transformer used as an overload sensor. To limit the output current at the level of 8 ... 10A, this resistor must be replaced with a 0.47Ω 1W resistor:

After such a replacement, the output current will not exceed 8 ... 10A even if we short-circuit the output wires.

Finally, you need to add a part of the circuit that will protect the unit from connecting the battery with reverse polarity (this is the only "home-made" part of the circuit). To do this, you need a regular automotive 12V relay (with four contacts) and two diodes per current 1A (I used 1N4007 diodes). In addition, to indicate the fact that the battery is connected and charging, you will need an LED in the case to be installed on the panel (green) and a 1kΩ 0.5W resistor. The scheme should be like this:

It works as follows: when the battery is connected to the output with the correct polarity, the relay is activated due to the energy remaining in the battery, and after its operation, the battery starts charging from the power supply through the closed contact of this relay, which is signaled by a lit LED. A diode connected in parallel to the relay coil is needed to prevent overvoltages on this coil when it is disconnected, arising due to self-induction EMF.

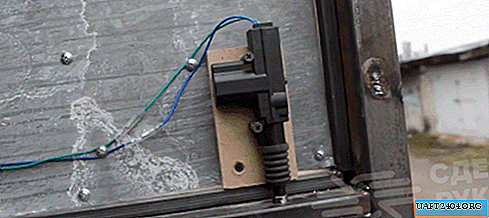

The relay is glued to the power supply radiator using a silicone sealant (silicone - because it remains flexible after "drying" and can withstand thermal loads, that is, compression-expansion during heating-cooling), and after the sealant "dries" on the relay contacts other components are mounted:

The wires to the battery are selected flexible, with a cross-section of 2.5 mm2, have a length of about 1 meter and end with "crocodiles" for connecting to the battery. To secure these wires in the device case, two nylon ties were used threaded into the holes of the radiator (the holes in the radiator must be pre-drilled).

That's all, actually:

In conclusion, all the labels were removed from the power supply housing and a home-made sticker was glued with new characteristics of the device:

The disadvantages of the resulting charger should include the lack of any indication of the degree of charge of the battery, which makes it unclear - is the battery charged or not? However, in practice it has been established that in a day (24 hours) a regular car battery with a capacity of 55A · h has time to fully charge.

The advantages include the fact that with this charger, the battery can “stand on charge” for any length of time and nothing bad will happen - the battery will be charged, but will not “recharge” and will not deteriorate.

Share

Pin

Tweet

Send

Share

Send